ÅF and Kreera design large rail project with Trimble´s BIM solution

Multidisciplinary BIM modelling of the Maland rail project in Sweden provides better project collaboration and results. Geographically spread design engineers in Gävle, Malmö and Sundsvall are collaboratively designing in Novapoint sharing a joint Quadri model for road, rail, terrain and water/sewer.

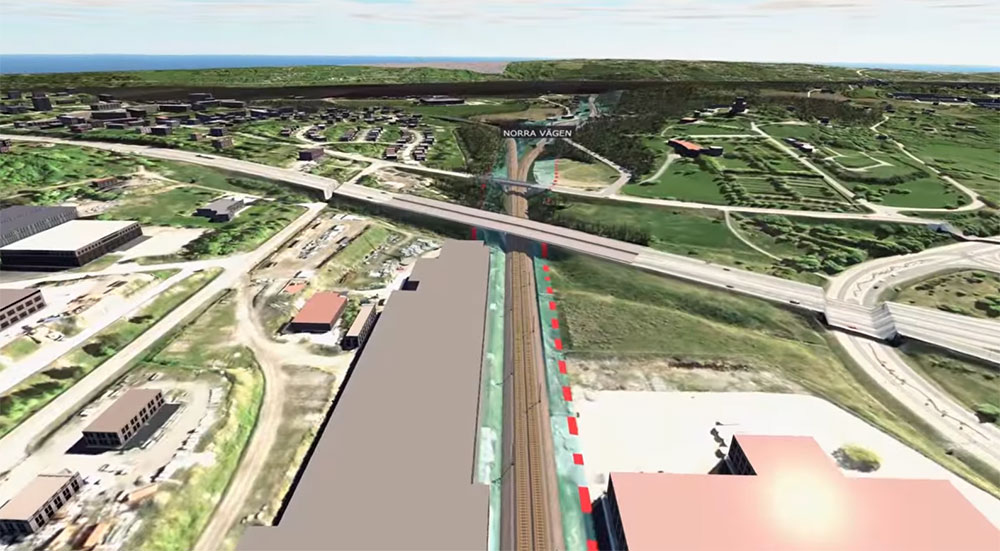

Illustration/graphic from Trafikverket: http://bit.ly/1X6f90J

ÅF has the main contract with Trafikverket (the Swedish Transport Administration) and Kreera is their subcontractor in the Maland project (outside the town of Sundsvall). Trafikverket plans to build a new double-track railway connection between the Tunadal track and the Ådal railway line, plus modernizing the Tunadal track. The new rail connection will make it possible to move freight away from roads to rail, leading to major environmental benefits and growth in the Sundsvall region.

ÅF's assignment is to design the meeting track triangle at Maland and the upgrading of the Tunadals track, including railway plans, system documents as well as construction documents.

“The project is divided into three parts, and we are now starting the detail design of the first part which is about upgrading and construction of a new rail meeting track in Birsta,” says Tobias Johansson. He is a road and terrain engineer at ÅF Infrastructure AB, and is in charge of the public roads in the project.

Everything in one single model

“As the technology and project competence resides at three different locations across the country, we gain a great deal of benefit from using a shared model server that all engineers are working with,” Johansson continues. “Using Novapoint's various discipline applications to design both road, rail, terrain and water/sewer, and by assembling everything in one single Quadri project model, we get a much better design basis compared to traditional 2D drawings and model files.”

The engineers import the actual rail track line as LandXML files from another tool into Novapoint Railway and Quadri. Kreera then uses Novapoint to design the rail groundwork and terrain under and around the track, as well as designing service roads and depots.

“The railway design becomes a little hybrid this way, but we find it very practical to see everything in a joint model,” says Johansson. “This is why we have chosen this method. It will not be a double job either, but more like a standard section you put in. It is only the macadam and up. The rest has to be designed in any case. That design is done in Novapoint Railway and the other Novapoint tools, including dewatering and adjacent terrains and roads.”

“This way we get a complete and always updated model that all stakeholders can share and relate to. Which is the very point of using Quadri,” says Tobias Johansson.

Better teamwork

"Eventually it becomes a quite big model to manage, with large amounts of data and many details,” adds Kreera´s Johan Malmström. “But this is not a big issue. On the contrary, the beauty of Quadri is that different disciplines can work together in the same model, and through this get a common project understanding. Everyone immediately sees and understands what the current data is, avoiding incorrect or non-updated data.”

Johan Malmström is a terrain and railway engineer at Kreera Samhällsbyggnad AB, a young Malmö-based engineering consulting company with 13 employees. In the Maland project his job is the design and engineering of the actual railroad and the terrain surrounding it.

Confident design

“Everything becomes readily accessible and clear to all parties,” he continues. “When you sit there and design, it's a great advantage to see all the relevant disciplines in 3D, twist and turn the model – and for example see that two roads that are supposed to meet, really do that at the detail level. This way you get more confident that your design is correct.”

“I am very positive to using the model. The Quadri model database makes a big difference,” ÅF´s Tobias Johansson points out. “Seeing all the disciplines and details in 3D and seeing how everything is connected and playing together is a very big advantage.”

“Not the least that you can see everything simultaneously and see what happens when you make changes. It's not like before when you were working separately and often could be taken aback when you finally put together all the drawings. Now you can continuously design your discipline piece and visually detect collisions with other disciplines and quickly make changes when needed. You can collaborate and put together the project in a much better way than working traditionally.”

Faster and confident

"This way, we can faster discover things that are incorrect and mistakes being done, and then make improvements," adds Johan Malmström at Kreera.

“Everything becomes more graphic and clear. In the traditional 2D way, it may take a week to get coordinated feedback on what you have done. If the model is shared well, this way of engineering goes much faster and becomes more confident.

In addition you may put in other objects in the model, such as existing drainage, houses and other building structures – which also becomes a visual strength in the further design.

The fact that the project team is spread geographically in Malmö, Gävle and Sundsvall is not a problem for the engineers. They communicate well both through the Quadri model in the Cloud and via Skype. The need for physical meetings is reduced to a minimum.

Another fact that also is special about this project is that they have a very short time to work out the construction documents. In 2018 the construction will start. So now is the time for detailed design for ÅF´s and Kreera´s engineers.