Svevia shows the way in model-based construction of infrastructure

The Swedish contractor Svevia is experiencing great benefits using the BIM model as construction source and project support in road projects. Svevia has done this in two new road projects in Stockholm – exemplary for future infrastructure construction.

The projects in question are located in Flemingsberg and Västra Länna outside Stockholm. In conjunction with future repairs of railway bridges in central Stockholm a new rail track etc. had to be built at Flemingsberg station. This meant that the roads in the area had to be rebuilt.

Model-based construction

Since the construction time had to be very short, only 6-7 months, it was effective to use the 3D model as basis for the construction. Not drawings. Svevia therefore engaged Wai-lok Lam from Vianova Systems as a specialist. The objective was to exploit the model optimally, both as a source for construction and in project management.

By using QuadriDCM as the collaboration model, Svevia and their consultants had continuous access to an updated project model in the whole construction process – simplifying the process largely.

“For us it has been very beneficial to use QuadriDCM as a collaboration solution, and to visualize for Trafikverket (The Swedish Road Administration) how we planned the different stages of production”, says Mathias Stenemyr, Production Manager at Svevia.

“We have used QuadriDCM to visualize, quantify and to simulate the construction work, for example traffic arrangement plans. The construction model in QuadriDCM has proved to be a very useful tool in this respect. It makes it easy to understand what to do and how we intend to carry out the work”, says Stenemyr.

Smart construction model

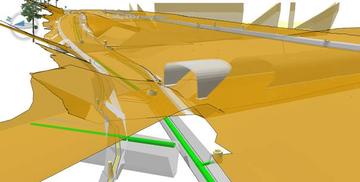

Vianova Systems´ Wai-lok Lam and a few others built the actual project model, working from various job sites using QuadriDCM in the cloud. All information is hence gathered in one place; both roads, water and sewer, ditches and road marking. It was even possible to put traffic arrangement plans and traffic rescheduling into the model.

“The model itself is not that big, but it is quite complex”, continues Lam. “It's only a road junction that is being moved, but there is very much infrastructure under ground that had to be changed. It was therefore essential to work smart and efficiently and without errors to succeed with the project. Having been possible for several people to work concurrently with the model we have been able to build the model in a faster way.”

Optimization and machine control

“By using Novapoint W&S we have also worked directly with machine control of the water and sewer excavations – hence reducing material waste and time spent in connection with the ordering and installation of pipes and stuff.”

Field engineers have retrieved machine control data and quantities directly from the model in real time. The fact that the model is available updated in 3D at all times, and you can easily generate sections from the model, allows it also to be used to disseminate information to supervisors and workers.

Better decisions and control

“Using the model, we have had work meetings every week to show what the upcoming work tasks consist in”, tells Wai-lok Lam. “A 3D model illustrates this much better than drawings. Everyone get insight and understand much better how the job should be done – avoiding misunderstandings and getting a safe and efficient construction process.”

Svevia has therefore also used the model in the same way in relation with their client. Everyone can easily see conflicts or errors in the dynamic model.

“During our technical meetings we could together with Trafikverket make quicker and safer decisions using the model”, says Lam.